Yes, you can cut aluminum with a miter saw, but you need the right blade, such as a carbide-tipped non-ferrous metal-cutting blade. Follow these steps:

- Wear safety glasses, hearing protection, and a dust mask.

- Clamp it securely to prevent movement.

- Lower the saw’s RPM for metal cutting and use a slower feed rate.

- Use a cutting fluid or lubricant to prevent overheating and achieve cleaner cuts.

- Experiment on scrap aluminum first to ensure the right settings.

- Cutting metal may cause more wear on the saw, so consider a dedicated setup for metal work if you do it frequently.

How to select the right tools for cutting aluminum with a miter saw?

Always follow manufacturer instructions for your specific miter saw and safety gear, and prioritize safe work practices at all times.

List of Tools and Materials Needed for Aluminum Cutting

Miter Saw: A high-quality miter saw suitable for cutting metal, preferably one with a carbide-tipped blade.

Aluminum Stock: The aluminum material you intend to cut. Ensure it is clean and free of any debris or foreign objects.

Measuring and Marking Tools:

- Tape measure or ruler for precise measurements.

- Pencil or marker for marking cut lines accurately.

- Combination square or angle finder for making precise angles.

Clamps: These are essential for securing the aluminum stock in place, preventing it from moving during cutting.

Safety Gear: While we will discuss safety gear in detail in the next section (B), it’s crucial to mention its importance here as well.

Cutting Lubricant: Optional but recommended, especially for thick aluminum. Lubricants like cutting oil or wax can help reduce friction and prolong blade life.

Workbench or Saw Stand: An elevated, stable surface to support the miter saw and workpiece, ensuring a comfortable working height.

Dust Collection System: If available, a dust collection system can help maintain a clean workspace by capturing aluminum dust and debris.

How to achieve precise cuts with a miter saw on aluminum?

Practice on scrap pieces before working on your actual project to familiarize yourself with the process and improve your skills.

Setting up the Miter Saw for Aluminum Cutting

Select the Appropriate Blade: Begin by choosing a carbide-tipped saw blade designed for cutting non-ferrous metals like aluminum. Ensure that the blade is sharp and in good condition.

Some miter saws come with adjustable blade speeds. If yours has this feature, set it to a lower speed suitable for cutting aluminum. Lower speeds reduce heat buildup and produce cleaner cuts.

In addition, use clamps to firmly secure the aluminum stock to the saw’s table. Ensure it’s stable and won’t move during cutting. Avoid placing your hands near the blade.

However, if you need to make angled cuts, adjust the miter and bevel angles on the saw according to your project requirements.

Marking and Measuring the Aluminum

Take accurate measurements on the aluminum stock, using a tape measure and a combination square or angle finder for angles. Double-check your measurements before marking.

Moreover, use a pencil or marker to mark the cut line on the aluminum. You can also use masking tape to mark the line and reduce the risk of chipping or splintering.

Account for the width of the saw blade (kerf) in your measurements. The kerf width can vary depending on the blade you’re using.

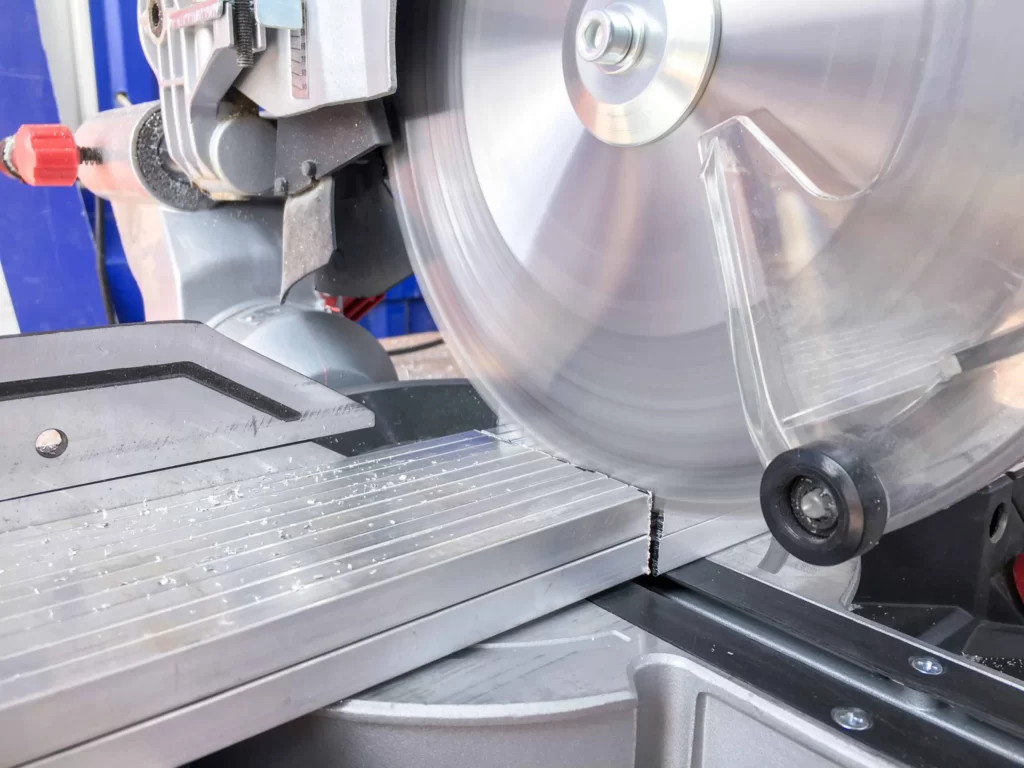

Making the Cut

Ensure the aluminum stock is flush against the saw’s fence or base, depending on your saw’s design. Maintain a firm grip on the stock throughout the cut.

Turn on the miter saw and allow it to reach full speed before making the cut. Always keep both hands on the saw’s handle and the stock.

Begin the cut slowly, allowing the blade to gradually penetrate the aluminum. Applying too much pressure too quickly can result in rough cuts or blade damage.

If you’re cutting thick aluminum, applying a cutting lubricant can help reduce friction and heat, resulting in smoother cuts.

Continue pushing the saw through the aluminum until you complete the cut. Release the trigger only after the blade has fully exited the material.

Troubleshooting Common Issues

If the cut edges are rough or jagged, it could be due to a dull blade. Consider sharpening or replacing the blade.

Overheating can cause melting or warping of the aluminum. Use a slower blade speed, if possible, and apply cutting lubricant to cool the blade.

However, if the aluminum stock binds or pinches the blade during the cut, stop immediately and release the stock. Ensure it’s properly secured and free of debris before continuing.

Check your measurements and saw settings to ensure accuracy. If necessary, recalibrate the miter and bevel angles.

If you encounter any safety concerns, such as sparks, stop immediately and address the issue. Ensure safety gear is worn correctly and that the work area is clear of flammable materials.

Final Words

In conclusion, we’ve explored the essentials of cutting aluminum with a miter saw. We learned how to select the right tools and materials, emphasizing safety gear.

Additionally, we went through a step-by-step guide on setting up the miter saw, measuring and marking the aluminum, making the cut, and troubleshooting common issues.

By following these guidelines, you can confidently and safely tackle your aluminum cutting projects with precision and efficiency.

Always prioritize safety, and practice, and enjoy the satisfaction of creating clean, accurate cuts for your DIY endeavors.