Jigsaws are versatile power tools used in woodworking, metalworking, and various construction projects. One critical component that significantly impacts their performance is the type of blade they employ. Two commonly used blade types are the T Shank and U Shank, each with its own set of characteristics, advantages, and ideal applications.

How Can You Define T-Shank and U-Shank Blades?

T-Shank and U-Shank blades are two distinct types of blades used in jigsaw tools, each characterized by their unique shapes and attachment mechanisms:

T-Shank Blades

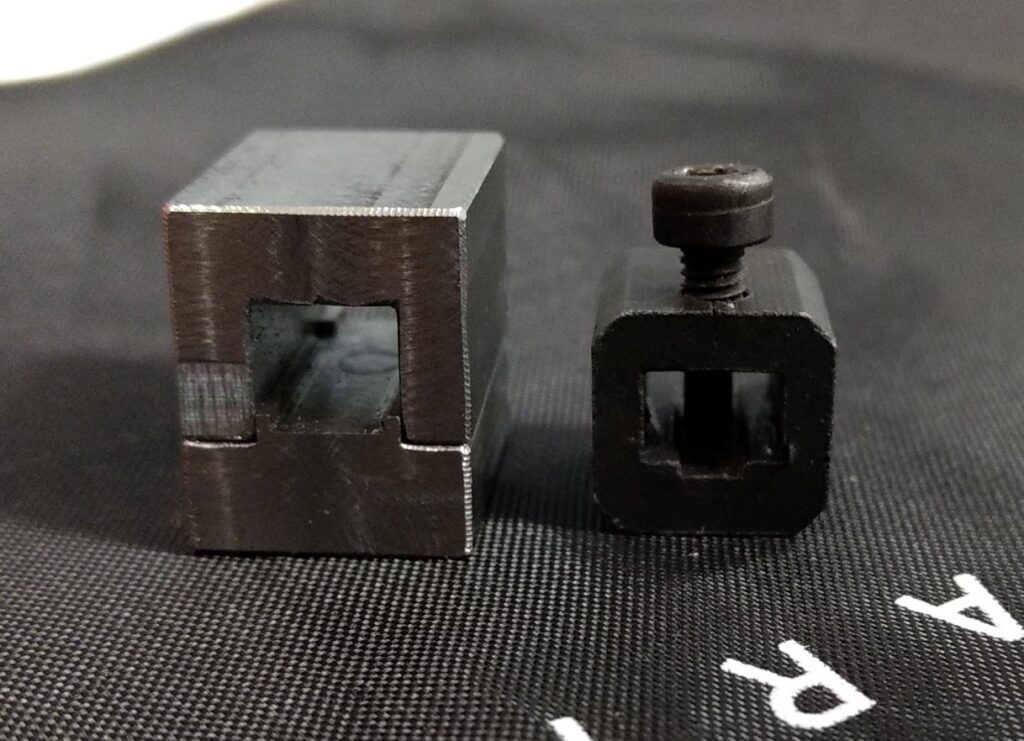

T-Shank blades feature a tang that resembles the letter “T,” which securely locks into the jigsaw’s chuck mechanism. This design ensures a quick and tool-less blade change, making it convenient for users to switch between different blade types during a project. T-Shank blades are widely compatible with most modern jigsaw models, providing a secure and stable grip.

U-Shank Blades

U-Shank blades, on the other hand, have a shape resembling the letter “U” and require a screw to hold them in place within the jigsaw. This design necessitates the use of a tool (usually an Allen key) for blade changes, which can be slightly more time-consuming compared to T-Shank blades. U-Shank blades are typically associated with older jigsaw models, although some newer jigsaws still support this blade type.

What Are The Difference Between T Shank and U Shank Blades?

T-Shank blades offer superior convenience, wider compatibility, and enhanced stability, making them a popular choice for most users, especially those with modern jigsaw models. On the other hand, U-Shank blades are more associated with older or specific jigsaws, requiring additional tools for blade changes and potentially providing slightly less stability during operation.

Convenience and Ease of Use

T-Shank Blades

T-Shank blades are engineered with a quick-release, tool-less mechanism. They feature a unique design that allows users to change blades swiftly and effortlessly. This feature is especially beneficial during time-sensitive projects or when frequent blade changes are required.

The simplicity of the T-Shank mechanism makes it more user-friendly, eliminating the need for extra tools or accessories. It allows for uninterrupted workflow, as users can switch blades on the fly without interrupting their task at hand.

The ease of use associated with T-Shank blades promotes increased efficiency, particularly in scenarios where time is critical or when working on intricate projects that demand frequent blade changes for various cutting requirements.

U-Shank Blades

Unlike T-Shank blades, U-Shank blades require a dedicated tool, typically an Allen key or a screwdriver, for blade changes. This tool-dependent process adds an extra step to the blade replacement procedure, contributing to a slightly less streamlined workflow.

The need for an additional tool to change U-Shank blades may lead to slightly longer downtimes during projects. Users must pause their work to fetch and use the tool for blade replacement, causing a minor interruption in their workflow.

Compatibility

T-Shank Blades

T-Shank blades have become the industry standard in modern jigsaw models. Manufacturers have widely adopted this design, making T-Shank blades compatible with the majority of new jigsaws available in the market.

The widespread adoption of T-Shank blades means they are compatible with various jigsaw brands and models, offering users a broader range of options and ease of blade replacement.

U-Shank Blades

U-Shank blades are typically found in older or specific jigsaw models that were manufactured before the widespread adoption of T-Shank blades. They might still be relevant for those who possess such legacy equipment but might not be compatible with newer jigsaw models, limiting their versatility.

Stability and Security

T-Shank Blades

T-Shank blades are designed to fit snugly within the chuck mechanism of the jigsaw. This secure fit minimizes blade wobbling during operation, resulting in more stable and precise cuts.

The stability provided by the T-Shank design enables users to achieve finer and more accurate cuts, especially crucial in intricate woodworking or detailed projects where precision is paramount.

U-Shank Blades

The attachment system of U-Shank blades, which involves a screw or similar mechanism, may result in a bit more play or movement compared to T-Shank blades. While still capable of providing adequate stability, they might not match the precision offered by T-Shank blades due to potential minor movements during operation.

Conclusion

Both T-Shank and U-Shank blades have their distinct advantages and applications. The choice between these blade types primarily depends on the jigsaw model being used and the specific requirements of the project. While T-Shank blades offer ease of use, compatibility, and stability, U-Shank blades remain relevant for certain older models and standard cutting tasks.